Piston Compressors vs Screw Compressors: Technical Comparison & Ice Plant Applications

Ⅰ.Core working principle differences

1.Working Principle:

Piston compressor: Based on the principle of reciprocating motion. The motor drives the crankshaft to rotate, which in turn drives the piston to move back and forth in a straight line within the cylinder. During the intake process, the intake valve opens and gas enters the cylinder; during compression, the intake valve closes and the piston compresses the gas; during exhaust, the exhaust valve opens and the compressed gas is discharged. This is an intermittent process.

Screw compressor: Based on the principle of rotational motion. It mainly consists of a pair of intermeshing male rotor (convex teeth) and female rotor (grooves). The motor drives the male rotor to rotate, which in turn drives the female rotor to rotate in the opposite direction. As the rotors rotate, the volume between the teeth and grooves moves axially from the suction end to the discharge end. Gas is continuously drawn in, trapped in the inter-tooth volume, compressed (volume reduction), and finally discharged from the discharge end. This is a continuous process.

2.Work Characteristics:

Piston compressor: Output in pulsed form, with relatively high vibration and noise. Volume adjustment is usually achieved through cylinder disengagement (deactivating some cylinders), frequency variation (more complex but with limited effect), or start-stop control.

Screw compressor: It provides a continuous and stable airflow output, with relatively low vibration and noise (especially for oil-injected levers). The exhaust volume adjustment is very flexible and efficient, with main methods including slide valve adjustment (stepless adjustment), variable frequency speed control, and plunger valve adjustment, etc.

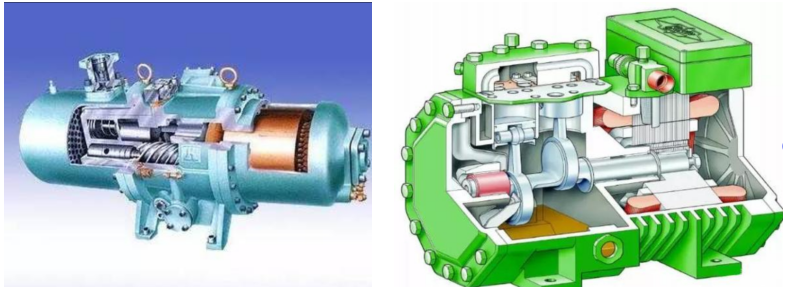

3.Complexity of structure:

Piston compressor: The structure is relatively simple, but there are many components (such as crankshaft, connecting rod, piston, piston rings, valves, cylinder liners, etc.) and many wear-prone parts.

Screw compressor: The structure is relatively compact (smaller in volume compared to the same displacement), with a small number of components (mainly including rotors, bearings, shaft seals, slide valves, etc.), and the core rotor has a high durability.

4.Lubrication and Cooling:

Piston compressor: It usually adopts splash lubrication or pressure lubrication. The lubricating oil mainly lubricates the moving parts (crankshaft, connecting rod, piston pin, etc.), and a small amount enters the cylinder to participate in sealing and cooling. Cooling mainly relies on the cooling water jacket or heat sink outside the cylinder (air-cooled).

Screw compressor: A large amount of lubricating oil is injected into the compression chamber. The lubricating oil serves to lubricate the rotor bearings, seal the rotor clearance, cool the compressed gas, and reduce noise. An efficient oil separator and oil cooling system are required. The cooling effect is very good.

II. Application and Differences in Ice Stations

The core task of an ice station is to continuously and stably provide low-temperature cooling to the ice rink or ice-making equipment. The refrigeration system is its core component, and the compressor is the heart of the refrigeration system. Ice stations typically use ammonia (R717) or refrigerants such as R507A, R134a as the refrigerants.

1.Common application:

Both can be used in the refrigeration system of the ice station, as a low-pressure stage compressor or a high-pressure stage compressor (in a cascade or double-stage system).

Both require a matching condenser, evaporator (ice field pipes), throttling device, control system, etc.

The goal is to compress the refrigerant, complete the refrigeration cycle, and remove the heat from the ice surface.

2. Application Differences and Selection Considerations:

System Size and Cooling Demand:

Piston Compressor: In small community ice rinks, training ice rinks, seasonal ice rinks, or ice-making machines where the cooling demand is relatively small (such as from a few dozen to several hundred kilowatts of cooling capacity), piston compressors still have applications due to their lower initial investment costs. They are also commonly used as high-pressure compressors in large systems.

Screw compressor: In large commercial ice rinks, competition venues’ ice rinks, ice rinks that operate throughout the year, and large ice-making plants where the cooling demand is high (typically ranging from several hundred kilowatts to several megawatts), the lubricating oil pump is the absolute mainstream. Its advantages such as large single-unit displacement, small footprint, flexible adjustment, and stable and reliable operation are extremely prominent.

3.Operating conditions and efficiency:

The evaporation temperature of the ice rink is usually between -10°C and -15°C (the ice surface temperature is around -5°C), which falls under medium-low temperature applications. Under this common operating condition:

Piston compressor: The full-load efficiency may not be low, but the load fluctuation of the ice rink is significant (changes in the number of skaters and environmental temperature). The piston compressor incurs significant efficiency loss under partial load (through cylinder unloading), and the proportion of power consumption decrease during unloading is much smaller than the proportion of cooling capacity decrease, resulting in a significant reduction in the partial load energy efficiency ratio (COP).

Screw compressor: Especially the oil-injected screw machine with slide valve adjustment, its efficiency decreases gradually under partial load conditions (with slide valve adjustment), while the energy efficiency ratio (COP) remains at a relatively high level. Variable frequency screw machines perform better in such variable load conditions, enabling nearly linear energy regulation and achieving significant energy-saving effects. Screw machines are more suitable for scenarios such as ice rinks where they need to operate under partial load for a long time.

4.Reliability and Maintenance:

Piston compressor: It has many vulnerable parts (such as valves, piston rings, etc.), and the maintenance frequency is high (it may need to be inspected and maintained every few thousand hours of operation). The risk of unexpected shutdown is relatively high. For professional ice rinks that require high reliability (such as competition venues), the maintenance burden and potential risks are drawbacks.

Screw compressor: The core component (rotor) has a long lifespan, requires few maintenance points (mainly oil, filter elements, and bearings), has a long maintenance cycle (usually 10,000 to 20,000 hours or longer), and has high operational reliability. This is crucial for ice stations that need continuous and stable operation and have limited maintenance windows (especially for large commercial ice rinks). Shutdown means the ice surface temperature rises and even melts, resulting in significant losses.

Ⅲ.Key points for ice plant selection:

Cooling capacity requirements: Small cooling capacity can be provided by piston compressors (cost-oriented); medium to large cooling capacity must be provided by screw compressors (performance, efficiency, and reliability-oriented).

Operating mode and load variation: For an ice plant that operates throughout the year and has significant load fluctuations, the regulating performance and partial load efficiency of the screw machine are extremely advantageous.

Reliability requirements: For professional ice plants and in scenarios where downtime must be avoided, the high reliability of screw machines is an essential guarantee.

Noise and vibration limitation: In situations where environmental impact is a high priority, screw machines are the better choice.

Maintenance costs and convenience: The long maintenance cycle and low maintenance frequency of screw machines can significantly reduce long-term operating costs.

Long-term energy efficiency cost: Although the initial investment of screw compressors is high, their excellent part-load efficiency can save a significant amount of electricity during the long-term operation of the ice plant, and usually has a lower total life cycle cost.

Therefore, in modern ice plants, especially in large and medium-sized ice plants and ice-making facilities, screw compressors have become the dominant technology due to their high efficiency, reliability, smooth operation, and ease of adjustment. Piston compressors, on the other hand, retain their position in specific small-scale or low-cost application scenarios.

To explore more industry refrigeration application solutions, please visit the THERMOJINN official website [www.thermojinn.com]

Contact information

Name:Dennis wen

Number:+86180501688

Email:denniswen@thermojinn.com

Post time: Aug-14-2025