High-Performance 1-40 Ton/ 24hours Versatile Block Ice Making Machine for Food Processing and Fishery

Thermojinn Direct Cooling Block Ice Machine

1. Applying Modular design,Small footprint and simple on-site installation.

2. PLC control, automatic water replenishment, deicing and Ice delivery(optional), simple operation and low failure rate.

3. It can provide designed ice storage, ice delivery and ice breaking systems to save manpower and improve efficiency.

4. Not use coolant, no brine, no strong corrosion.

△ Ice making evaporator module

Ice cans: High quality aluminum alloy ice cans, galvanized or stainless steel support frame, made of clean and sanitary ice blocks, which can be directly eaten.

Water input system:The specially designed water adding device is simple to operate, accurate to control the amount of water added, and avoids water waste.

Defrosting system: Hot fluorine defrosting system, soft hot gas supply, efficient deicing, and no damage to the ice surface.

Ice dropping system:Manual / automatic hydraulic deicing lifting platform, simple and stable operation, safe deicing and non fragile.

△ Compressor unit module:

• compressor - Hanbell/Frascold/XM/Mycom and etc.

• Vessels - liquid receiver, oil separator (when needed), suction accumulator;

• Piping - suction and discharge;

• Valves - AMG

• Control Panel - ThermoJinn

△Condensing module.

• Water cooling tower or

• Evaporative condenser or

• Air-cooled condenser

Block ice size: Weight and dimension can be customized, Thermojinn standard block ice weight and dimension are listed below for your reference:

Ice Block Dimension:

|

Weight (kg/block) |

Dimension (mm) |

Pro. Time per batch (hr) |

Batches per day (times) |

|

5 |

120*100*600 |

4.5 |

4 |

|

10 |

230*100*600 |

4.5 |

4 |

|

15 |

330*100*600 |

4.5 |

4 |

|

20 |

300*125*800 |

6.5 |

3 |

|

25 |

350*125*800 |

6.5 |

3 |

|

30 |

280*170*800 |

9.5 |

2 |

|

40 |

350*170*800 |

9.5 |

2 |

|

50 |

450*170*800 |

9.5 |

2 |

|

100 |

550*220*1000 |

14 |

1.5 |

Thermojinn direct cooling block ice machine is different from other brands of ice machines, When calculating the ice making production batch, it not only considers the ice making time, but also reserves the time for users to deicing, move ice and add water.

Direct cooling ice machine parameter:

|

Model |

Capacity (t/24hr) |

Ice Block weight (kg) | Refrigeration capacity (kw) | Install Power (kw) | Power consumption (kw) | Dimension (mm) | Operating weight (kg) |

| TJB-50DW |

5 |

50 |

38 |

30 |

23 |

4800x1800x2200 |

3800 |

| TJB-100DW |

10 |

50 |

76 |

50 |

38 |

7000x2200x2550 |

4950 |

| TJB-150DW |

15 |

50 |

114 |

75 |

55 |

10000x2200x2550 |

7250 |

| TJB-200DW |

20 |

50 |

152 |

100 |

73 |

11800x2200x2550 |

8670 |

| TJB-250DW |

25 |

50 |

190 |

120 |

85 |

11800x2912x2550 |

11500 |

| TJB-300DW |

30 |

50 |

228 |

150 |

103 |

11800x3012x2550 |

12500 |

W- Water cooled condenser with cooling tower. Have air cooled condenser /Evaporative condenser for optional.

* Refrigerant:R22/R404A/R507. Power: 380V/3P/50HZ.

* Condition: Ambient temperature:35ºC. Wet-B: 25ºC. Water inlet temperature: 20ºC

* Ice Block weight has 25kg/50kg optional,The Dimension of the equipment will vary depending on the size of the ice

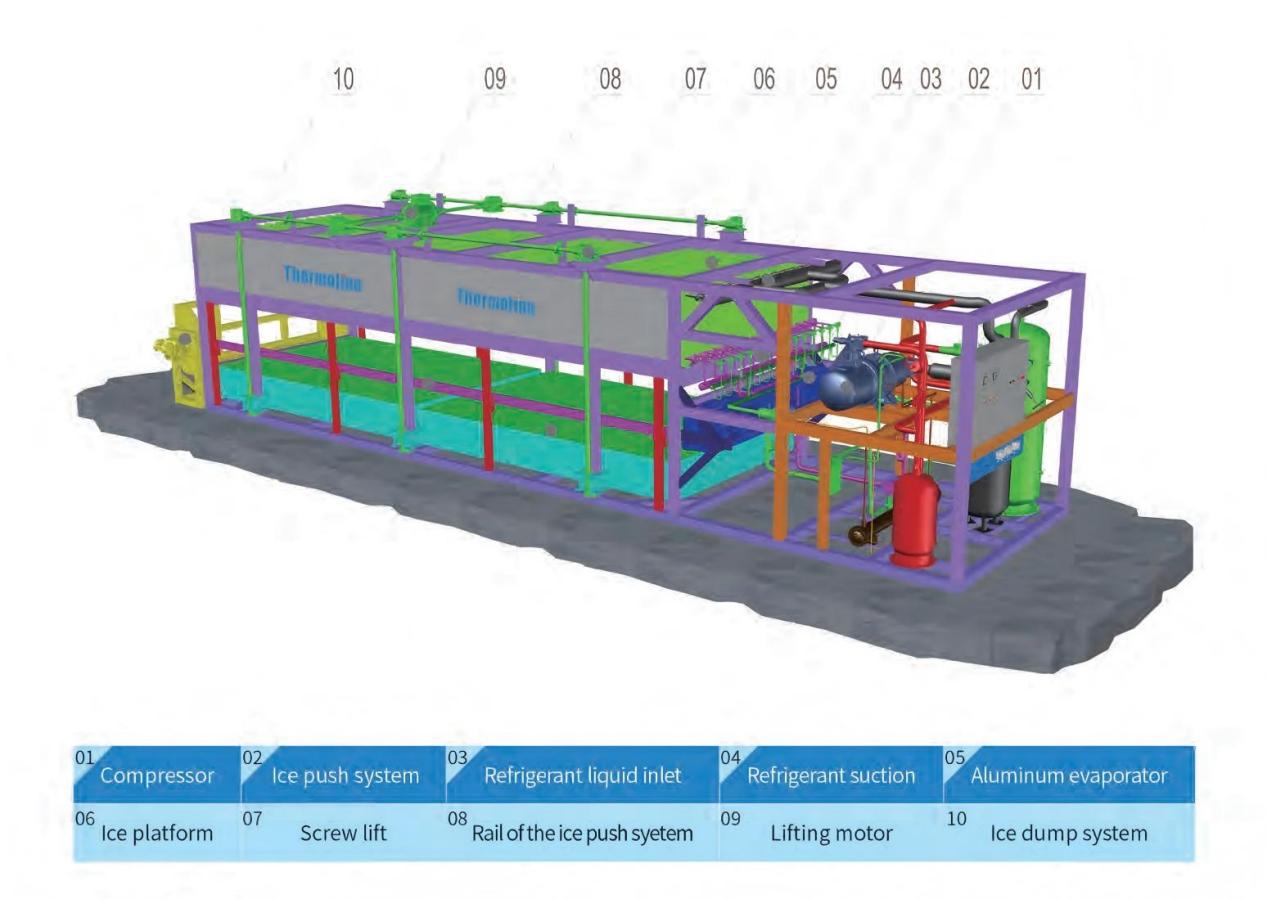

The diagram of direct cooling block ice machine working principle

lce making model: Lifting motor (09) drives screw lift (07) running at corotation model, the ice platform (06) going up to the high-point and seal the bottom of the aluminum evaporator (05) with the silica strip, After that, full the water inthe mould of the aluminum evaporator (05). The compressor and refrigeration system running at ice making model,refrigerant liquid into the refrigerant liquid inlet (03) and direct heat exchange with the water in the mould of thealuminum evaporator (05), until the water cooling and all turns to the ice, refrigeration system stop automatic.

lce doffing model: Refrigeration system running at ice doffing model. The refrigerant hot gas into refrigerant suction (4)and heat exchange with the ice in the mould of the aluminum evaporator (05). The ice thawing and remove from themold of the aluminum evaporator (05),. And then lifting motor (09) drives screw lift (07) running at reverse the mode,ice platform (06) and all of the ice going down to the ground, refrigeration system stop automatic.

lce push system (optional): lce push system (02) push all the ice on the ice platform (06) out to the left side.Ice dump system (Optional): lce dump system (10) running together with the ice push system (02), it oversets the iceone row by one row and ice is easy to move to the ice storage.

Some more features:

• Large evaporation area coil evaporator increases heat transfer efficiency, ensures long service time and corrosion resistance.

• Well insulated brine tank with high resistant epoxide coating.

• Heavy-duty overhead crane with 2 speeds for moving, lifting and tipping the ice cans.

• Ice thawing tank utilizes the exhaust heat from compressor, more energy saving.

• Modular design simplified equipment transportation and on-site installation process.

• Rivet and reinforced ice cans construction to extend its service life.

• Unique propeller blade processing technology to improve the efficiency of the agitator, increase the flow of salt water, accelerate ice making speed.

• Options of stainless-steel ice cans and galvanized steel ice cans.

• Touch screen, reserve function, 3G network remote fault alarm, 4G network remote video monitoring are available on request.·

Application Field:

PACKING & TRANSPORT: