About Thermojinn

THERMOJINN is a leading supplier specializing in industrial refrigeration and temperature control solutions. With years of experience in the industry, we are committed to providing customers with efficient, reliable and energy-saving refrigeration equipment. Relying on strong R&D capabilities, a strict quality control system and rich engineering experience, THERMOJINN's products are widely used in various industrial fields such as cold storage, food processing, chemical, pharmaceutical, plastic, and cold chain logistics. We are well aware of the strict requirements of industrial environments for equipment performance, stability and energy consumption. Therefore, we continuously optimize our technology and introduce high-performance products represented by evaporative condensers to help customers significantly reduce operating costs, enhance competitiveness, and fulfill environmental protection responsibilities.

The outstanding efficiency of the evaporative condenser

In the field of industrial refrigeration, energy consumption is often the "major component" of operating costs. Traditional water-cooled condensers consume a large amount of water, while air-cooled condensers suffer significant efficiency losses in high-temperature environments. How to balance efficiency, energy consumption and environmental adaptability? The evaporative condenser (Evaporative Condenser) of THERMOJINN, with its unique working principle and significant advantages, is becoming the preferred solution for an increasing number of industrial users.

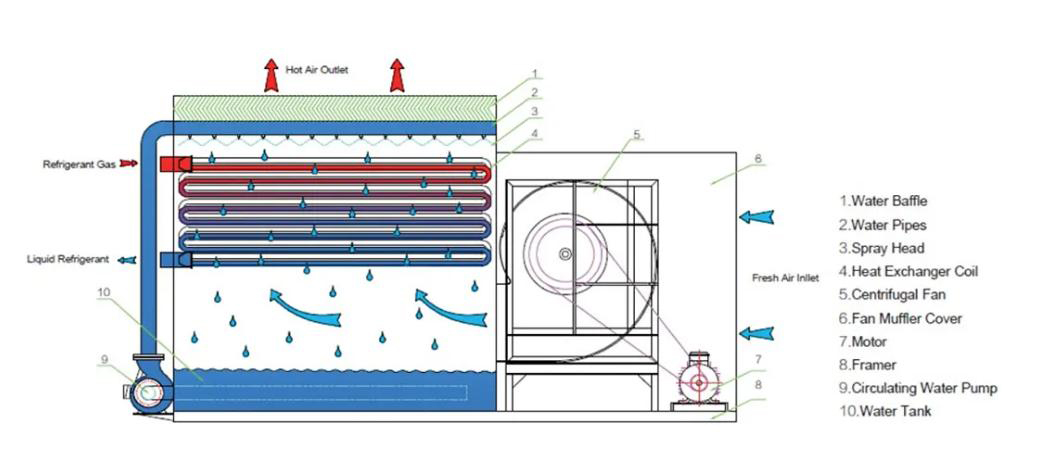

I.Core Principle

The design concept of the evaporative condenser is extremely ingenious. It ingeniously combines the efficient heat exchange of water cooling with the convenience of air cooling, and incorporates the natural force of water's latent heat of evaporation. The core working process is as follows:

1.Coil-type heat exchange: The high-temperature and high-pressure refrigerant vapor enters the coil located at the top of the equipment.

2. Water film coverage: The circulating pump draws water from the water tank and evenly sprays it onto the outer surface of the coil through the spray system, creating a dynamic water film.

3. Evaporation Heat Absorption: A powerful fan located beneath the coil sucks in air from the bottom or sides of the equipment. The air is forced to flow upward across the moist coil surface. The air comes into contact with the water film, and some of the water absorbs heat and rapidly evaporates (utilizing the large latent heat of evaporation of water to remove the heat).

4. Efficient Condensation: The heat of the refrigerant vapor within the coil is absorbed by the sensible heat of the water film and the latent heat of evaporation of water, thereby being efficiently condensed into liquid form.

5. Exhaust and Water Supply: Saturated moist air is discharged into the atmosphere by the fan. A small amount of water evaporated is replenished through the automatic Water Supply valve. The dissolved mineral impurities in the water are regularly discharged through the sewage valve to prevent scaling.

II.Core Advantages

1.Excellent energy-saving efficiency:

Approaching wet-bulb temperature condensation: Evaporative cooling enables the condensation temperature to approach or even reach the wet-bulb temperature of the environment, which is usually much lower than the dry-bulb temperature (especially in hot and dry regions where the difference is significant).

Significantly reduce compressor energy consumption: A lower condensing temperature directly means a decrease in the suction specific volume of the compressor and a reduction in the compression ratio, thereby significantly reducing the power consumption of the compressor. Compared with pure air-cooled systems, the energy-saving effect is generally up to 20% - 40% or even higher.

Fan and pump energy consumption optimization: THERMOJINN employs high-efficiency EC fans and variable-frequency pumps. It intelligently adjusts the operating status based on environmental temperature, humidity, and system load, further optimizing energy consumption during operation.

2.Efficient utilization of water resources:

The water consumption is only 1/3 to 1/4 of that of the water-cooling tower system: Since it mainly relies on the latent heat of water evaporation for heat dissipation, only the evaporated water and a small amount of wastewater need to be replenished. Compared with the water-cooling system (condenser + cooling tower) that requires a large amount of cooling water circulation and evaporation through the cooling tower for heat dissipation, its total water consumption is significantly reduced, and the water-saving effect is extremely remarkable.

3.Compact in size:

Highly integrated design: The evaporative condenser integrates the condensation coil, spray system, pump, water tank, fan and water collector into a compact enclosure. This eliminates the need for an independent cooling tower and a large cooling water pipeline system in the water cooling system, thus freeing up more space in the valuable factory area.

4.High adaptability to the environment:

Outstanding performance in high-temperature environments: In hot summers or in high-temperature areas, its characteristic of relying on wet-bulb temperature results in a much smaller performance degradation compared to air-cooled condensers, ensuring the continuous, stable and efficient operation of the system.

Reducing the heat island effect: Compared to air coolers which directly release a large amount of sensible heat into the environment, evaporative condensers mainly release moist air (with a large amount of latent heat), resulting in less thermal pollution to the environment.

5.Reduction in operation and maintenance costs:

The cost of water treatment is low: The amount of circulating water is small, and accordingly, the consumption of water treatment chemicals is also reduced.

Maintenance is relatively simple: The main maintenance tasks mainly involve regular cleaning of the coils (to prevent scaling), checking the nozzles, cleaning the water tank, and maintaining the fans and pumps, etc. Compared to the water-cooled tower system, it is easier to manage.

III. The exquisite quality of THERMOJINN evaporative condenser

High-efficiency heat transfer coil: Utilizing high-quality seamless steel pipes or stainless steel pipes, the surface undergoes special hydrophilic treatment (such as galvanization, epoxy coating, or proprietary coating), which enhances the water film spreading ability and corrosion resistance, maximizing the heat transfer efficiency and service life.

Intelligent control system: Equipped with advanced controllers, it enables functions such as starting/stopping of fans, speed regulation of fans, starting/stopping of water pumps, variable frequency control of water pumps, automatic water replenishment, high/low pressure protection, anti-freezing protection, and remote monitoring, ensuring safe, efficient and intelligent operation.

High-efficiency low-noise fan system: Utilizing axial flow fans with wide blades, large diameter and low rotational speed, or high-efficiency EC fans, this system ensures a large air volume while significantly reducing operating noise.

Effective water collection device: Multi-layer high-efficiency PVC water collector, effectively separating water droplets carried by air, reducing water leakage loss, and protecting the surrounding environment.

Sturdy and durable structure: The box body is made of hot-dip galvanized steel plate, stainless steel plate or high-quality aluminized zinc plate. The structure is stable and has strong corrosion resistance, suitable for various industrial environments.

Anti-freezing protection design (optional for cold regions): Offers various anti-freezing options such as coil drain valves, internal circulation heaters, and variable-speed fan controls to ensure the safety of equipment during cold seasons.

IV. Wide Range of Applications

THERMOJINN Evaporative Condensers are the ideal choice for industrial refrigeration scenarios including:

1.Large Cold Storage Warehouses & Cold Chain Logistics Centers

2.Food & Beverage Processing Plants (Slaughtering, Freezing, Chilling, Dairy, Beverages)

3.Chemical & Pharmaceutical Process Cooling.

4.Plastics Molding & Processing (Injection Molding, Extrusion, Blow Molding)

5.Central Air Conditioning Systems (Especially for large commercial or industrial buildings)

6.Ice Rinks & Ski Resort Refrigeration

7.Industrial Process Cooling

V. Choose THERMOJINN, Choose Efficiency & Reliability

Facing increasing pressure from energy costs and environmental regulations, selecting efficient refrigeration equipment is crucial for industrial enterprises pursuing sustainable development. THERMOJINN Evaporative Condensers, with their outstanding energy-saving characteristics, significant water conservation, compact footprint, and robust environmental adaptability, offer an economical, eco-friendly, and reliable solution for industrial refrigeration.

We provide not just equipment, but also expert selection support, installation guidance, and full lifecycle service guarantees. Let THERMOJINN be your powerful partner in upgrading your industrial refrigeration system, enhancing energy efficiency, and reducing operational costs!

Contact THERMOJINN professional team today for a customized evaporative condenser solution and embark on your journey towards industrial energy efficiency!

Email:info@thermojinn.com

Whatsapp:+8618050168821

Website:www.thermojinn.com

Post time: Jul-25-2025