In large-scale concrete projects such as dams, bridges, large foundations, and high-rise buildings, the hydration reaction of cement generates a significant amount of heat. If not properly controlled, excessive temperature differences between the interior and exterior of the concrete can lead to thermal stress cracks, seriously affecting the structural integrity, durability, and strength. Therefore, a concrete cooling system is of vital importance, and ice-making machines are one of the core equipment providing cold sources in such systems.

Ice is added to the water used for mixing concrete. The latent heat absorbed by the melting ice can very efficiently reduce the temperature of the concrete at the discharge port to the required standard (usually 7°C or even lower).

Ⅰ.Thermojinn flake ice machine

Thermojinn flake ice machine is an automated ice-making device that uses a refrigeration system to turn water into dry, loose, and irregularly shaped sheet-like ice. The ice produced by this machine is called "flake ice". Due to its high ice-making efficiency, excellent ice quality and ease of mixing with other materials, the plate ice machine has become the preferred equipment in many industrial processing and commercial cooling applications.

1. The working principle of the ice chip machine

Spraying water: The water is evenly sprayed onto the surface of a vertical or inclined, hollow cylindrical evaporator. The interior of the evaporator is filled with low-temperature refrigerant (such as ammonia or Freon), so the outer surface temperature of the evaporator is much lower than the freezing point of water.

Freezing: Water rapidly freezes on the surface of the low-temperature evaporator, forming a thin layer of ice.

Ice scraping: A rotating ice scraper driven by an electric motor works closely against the surface of the evaporator. As the evaporator rotates slowly, the ice scraper scrapes off the frozen layer on the surface.

Ice discharge: The ice fragments (i.e. flake ice) that have been scraped off fall through the ice discharge opening and enter the ice storage bin or are directly transported via the conveying system to the usage point.

Cycle: Unfrozen water will flow back into the water tank and be reused, entering the next ice-making cycle.

The entire process is fully automated and is precisely managed by the control system, enabling continuous production of ice cubes.

2. Characteristics of the ice flake

Shape: Irregular, dry, thin sheet-like, with a thickness usually ranging from 1 to 2 mm.

Temperature: Due to "dry ice", the temperature is extremely low, usually ranging from -5°C to -8°C, and the surface is dry and does not stick together.

Texture: Soft and dry, with good fluidity and no tendency to clump.

Greater specific surface area: Due to its sheet-like structure, the specific surface area per unit weight is extremely large.

Fast melting rate: The large surface area enables it to make full and rapid contact with the cooled object, with extremely high heat exchange efficiency and a very fast melting speed.

Ⅱ.The crucial role of the ice machine in the concrete cooling system

The ice flake machine is not merely an optional equipment in concrete production. In modern large-scale projects, it often serves as the key core equipment for ensuring the quality of concrete and controlling the project schedule. Its significant functions are mainly reflected in the following aspects:

1.Efficient and uniform temperature control

This is the most fundamental and important function of this ice flake machine.

1.1 Utilizing latent heat for efficient cooling:

The specific heat capacity of water is 4.2 kJ/kg·°C, which means that to raise the temperature of 1 kilogram of water by 1°C, 4.2 kilojoules of heat need to be absorbed.

The latent heat of ice melting is 334 kJ/kg. To melt 1 kilogram of 0°C ice into 0°C water, 334 kilojoules of heat need to be absorbed.

Comparison: The amount of heat absorbed when melting 1 kilogram of ice is equivalent to the amount of heat absorbed when lowering the temperature of 1 kilogram of water by nearly 80°C (334/4.2 ≈ 79.5).

Conclusion: The efficiency of using ice to cool concrete is much higher than simply using cold water. It can input a huge amount of "cold energy" into the concrete mixture without increasing the total water usage, thereby effectively reducing the outlet temperature of the machine to 7°C or even lower as required.

1.2 Rapid melting, uniform cooling:

The ice cube has a large surface area to volume ratio and is extremely thin in thickness. This enables it to melt instantly within a few seconds after entering the blender.

The rapid and thorough melting ensures that the coldness is distributed quickly and evenly throughout the concrete mixture, avoiding the risks of local overcooling or the presence of un-melted ice clumps, thereby guaranteeing the homogeneity and stability of the internal structure of the concrete. This is something that ice types that melt slowly, such as pipe ice, cannot achieve.

2.Achieve precise automated production - Enhance construction quality and efficiency

The modern flake ice making system has been fully integrated into the automated mixing station.

2.1 Precise measurement:

The dry and loose nature of the ice particles enables it to be precisely measured with high accuracy using weighing sensors or volumetric feeders. The control system can dynamically calculate and adjust the amount of ice added to each batch of material based on the current temperature and humidity of the aggregate, the ambient temperature, and the set target outlet temperature, achieving intelligent temperature control.

2.2 Seamless integration:

The ice blocks can be directly transported from the ice storage bin to the main material scale above the mixer or to a separate ice scale through a fully enclosed screw conveyor or a pneumatic conveying system. The entire process is fully automated and perfectly synchronized with the feeding processes of cement, aggregates, water and admixtures, ensuring the continuity of the production rhythm and the accuracy of the ratio.

3. Give the project greater flexibility and controllability

3.1 Adapting to demanding conditions:

In hot climates or when there is a large amount of heat released by high-strength cement, merely relying on pre-cooling the aggregates and using cold water may not be sufficient to reach the target temperature. Flake ice offers the most effective and reliable final cooling method, enabling the project to continue under various environmental conditions without delaying the schedule.

3.2 Optimize the mix ratio:

Since ice replaces part of the mixing water and has an extremely high cooling efficiency, engineers have greater flexibility when designing the mix ratio. Sometimes they can reduce the amount of expensive admixtures or optimize the amount of cement, achieving performance while potentially generating economic benefits.

4.Economic benefits and engineering reliability

4.1 Avoiding exorbitant restoration costs:

For large-volume concrete structures (such as dam piers), once serious cracks occur, the repair costs can easily reach tens of millions or even hundreds of millions of yuan, and they are often difficult to be completely repaired. Investing in an efficient ice-cutting system in the early stage is a highly cost-effective risk investment compared to the potential astronomical repair costs.

4.2 Ensure project progress:

The reliable temperature control system ensures that the quality of concrete on each side meets the requirements of the code, avoids shutdown, scrapping or rework caused by quality problems, and ensures the smooth progress of key project nodes.

The ice machine plays the dual roles of "precise temperature regulator" and "quality guardian" in the concrete cooling system. It is not merely about making ice; rather, through its unique ice-forming characteristics (rapid melting and easy transportation and measurement), it seamlessly integrates an extremely efficient cooling medium into the modern and automated concrete production process, thereby:

Physically, it effectively reduces the temperature of the concrete and eliminates the risk of temperature difference-induced cracks.

Chemically, creating an ideal low-temperature environment for the hydration of cement and optimizing the microstructure.

From an engineering perspective, ensure the construction quality, progress, and the long-term durability and safety of the final structure.

This is precisely why in almost all large-scale hydropower, nuclear power, bridge and port projects around the world, the ice-breaking system is an indispensable standard equipment in concrete mixing stations.

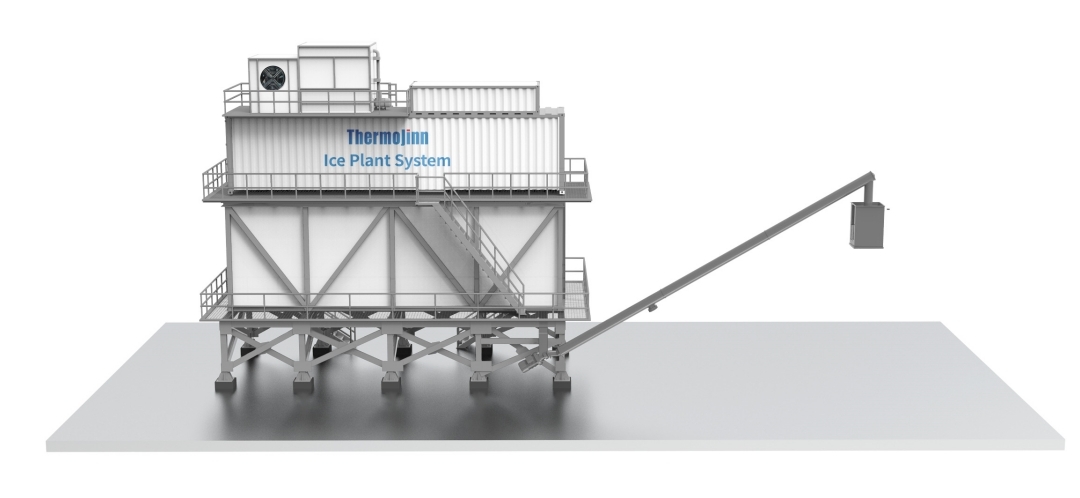

ThermoJinn's containerized flake ice plant offers an all-in-one solution featuring automated ice storagedelivery, and weighing systems. Designed for optimal efficiency, this plant includes a remote controlfunction, allowing for seamless operation and monitoring from any location. The flake ice plant ensuresconsistent ice production and distribution, making it ideal for various industrial applications that requireprecise ice management.

To explore more industry refrigeration application solutions, please visit the THERMOJINN official website [https://www.thermojinn.com/]

Contact information

Name: Dennis wen

Number: +8618050168821

Email: denniswen@thermojinn.com

Info@thermojinn.com

Post time: Aug-27-2025