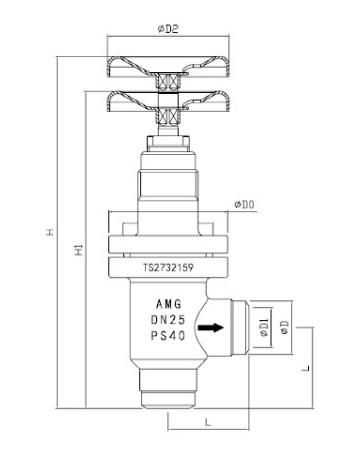

RVT15-80-D Forged steel straight-through stop valve

Technical Parameter

Nominal pressure: 4.0MPa

Applicable temperature: -50°c ~ +150°c

Test pressure: 6.0MPa

Applicable medium: ammonia, fluorine, propane, propylene , etc.

|

Name |

Model |

Size (mm) |

Weight (kg) |

|||||

|

φD |

φD1 |

L |

φD0 |

H1 |

H |

|||

|

RVT Series Right-angle Stop Valve |

RVT15-D |

21 |

15 |

40 |

65 |

168 |

183 |

1.2 |

|

RVT20-D |

25 |

20 |

40 |

65 |

168 |

183 |

1.3 |

|

|

RVT25-D |

32 |

25 |

51 |

75 |

200 |

223 |

2.1 |

|

|

RVT32-D |

38 |

32 |

51 |

75 |

200 |

223 |

2.2 |

|

|

RVT40-D |

45 |

40 |

60 |

95 |

246 |

290 |

3.8 |

|

|

RVT50-D |

57 |

50 |

64 |

95 |

246 |

290 |

4.0 |

|

|

RVT65-D |

76 |

65 |

75 |

105 |

265 |

300 |

7.2 |

|

|

RVT80-D |

89 |

80 |

80 |

115 |

305 |

345 |

8.3 |

|

Characteristics

● Optimal product design. Adoption of computer-aided design (CAD SolidWorks ).Applicable to all general-purpose refrigerants and non-corrosive gases and liquids, including ammonia, fluorine, propane and propylene.

● Perfect sealing performance. The moving part valve stem is provided with high-precision double O-ring and PTFE packing to ensure zero leakage. All sealing gaskets are environment- friendly asbestos-free ones that are resistant to both fluorine and ammonia.

● The back seal design enables convenient valve maintenance during system operation. The double-cone seal design ensures large flow capacity, small pressure drop and high efficiency.A special linkage structure between valve stem and valve clack is adopted so that the concentricity of valve clack is adjusted automatically to ensure valve closing tightness and minimize valve clack friction for prolonging service life.

● Compact structure, small size and light weight. Reducing freight cost, shortening installation time and lowing labor intensity.Best protection against rusting and corrosion. Special rust-proof materials are used on the surface. The internal and external surfaces are treated with special formula and process to ensure cleanness and rust-free. The stainless steel valve stem is polished by a special technique.

● Possibility of direct welding to steel pipe or brazing to copper pipe. Customer options are offered for either hand-wheel or sealed cap.Each valve is inspected strictly according to European standards.

For more details and different sizes, please contact us