Thermojinn Containerized Ice Plant

Product Information

ThermoJinn is a leading provider of HVAC/R solutions, specializing in concrete cooling systems.Our concrete cooling ice plants are designed to optimize the temperature control processes essential for large-scale concrete projects. These systems utilize advanced ice-making technologies,such as flake ice machines, to ensure consistent and efficient cooling, enhancing the quality and durability of the concrete.

Our commitment to innovation and reliability makes Thermojinn a trusted partner for construction projects requiring precise temperature regulation.

Containers:

lce makers/ Chiller units are assembled inside the 20' or 40' HQ container. Maxium capacity of ice plant in a single container can reach upto 86ton/day, maximum capcity of sinale container for chillerunit can reach upto 360ton/day.

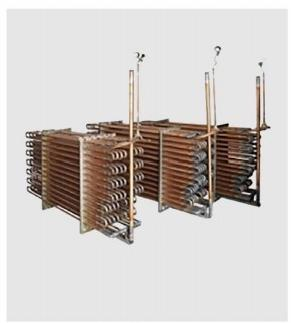

Evaporative Condensers:

TLC series Evaporative condenser is a high-efficiency solution designed with a full coil configuration which maximizes heat transfer by exposing a larger surface area to the evaporative cooling process. Without fillets,it reduces potential points of blockage and efficency drops.This design choice enhances the condenser's efficiency and reliability,ensuring consistent performance even under extreme working condition.

Auto Raking Ice Storage:

Thermojinnice storage automates the process of storing and distributing ice,ensuring a continuous supply without manual intervention.Equipped with a robust ice rake mechanism,it evenly distributes ice within the storage bin,preventing clumping and bridging.

Thermojinn's Ice Delivery Screw and Weighing Hopper system is a precision-engineered solution designed for accurate ice distribution and measurement in industrial settings.The Ice Delivery Screw efficiently transports ice from storage to the point of use,ensuring a steady and controlled flow Weighing

Hopper provides precise measurement of ice quantities before delivery.This integration allows for accurate dispensing based on specific requirements,reducing waste and optimizing resource use.

Control system

Thermojinn's Control Panels are sophisticatedly designed to monitor and manage ice storage and delivery operations with precision and ease.These control panels provide real-time monitoring of ice levels,storage conditions,and delivery processes,ensuring optimal performance and efficiency.

Ice Plant

ThermoJinn's containerized flake ice plant offers an all-in-one solution featuring automated ice storage, delivery,and weighing systems.Designed for optimal efficiency,this plant includes a remote control

function,allowing for seamless operation and monitoring from any location.The flake ice plant ensures consistent ice production and distribution,making it ideal for various industrial applications that require precise ice management.

Water Chille

ThermoJinn offers advanced containerized water chillers capable of reducing water outlet temperatures to as low as 1℃.These systems utilize a three-stage cooling process,efficiently cooling water from 40℃ down to 1℃ directly.The chillers are designed for high-performance cooling in various industrial applications,ensuring reliable and consistent temperature control.

Product Parameters

Flake Ice Plant

| Model | Cap. | Needed Ref.Cap. (kW) | Ins,Power (kW) | Cons.Power(kW) | Cons.Water(l/hr) | Running Weight(ton) |

| TJ-FIP20 | 20 | 100 | 83 | 67.23 | 1200 | 14.1 |

| TJ-FIP25 | 25 | 125 | 94 | 76.14 | 1730 | 16.3 |

| TJ-FIP30 | 30 | 150 | 117 | 94.77 | 2050 | 18.2 |

| TJ-FIP40 | 40 | 200 | 152 | 123.12 | 2700 | 25.1 |

| TJ-FIP50 | 50 | 250 | 176 | 142.56 | 3280 | 28.6 |

| TJ-FIP60 | 60 | 300 | 227 | 183.87 | 4010 | 31.2 |

| TJ-FIP70 | 70 | 350 | 265 | 214.65 | 4700 | 33.2 |

| TJ-FIP80 | 80 | 400 | 296 | 239.76 | 5900 | 36.1 |

| TJ-FIP90 | 90 | 450 | 377 | 298.6 | 6700 | 39.4 |

| TJ-FIP100 | 100 | 500 | 427 | 350.14 | 7400 | 42.1 |

Auto Ice Storage

| Model | Ice Storage Capacity (Ton) | Type | Length (mm) | Width (mm) | Height (mm) | Weight (Ton) |

| AIS 18 | 18 | Containerized | 12192 | 2438 | 2591 | 12.5 |

| AIS 23 | 23 | Containerized | 12192 | 2438 | 2896 | 13.5 |

| AIS 35 | 35 | Combined | 12192 | 3550 | 3720 | 20.5 |

| AIS 40 | 40 | Combined | 12192 | 4150 | 3720 | 22.5 |

| AIS 50 | 50 | Combined | 12192 | 5195 | 3570 | 23.5 |

| AIS 60 | 60 | Combined | 12192 | 5195 | 3970 | 26.0 |

| AIS 65 | 65 | Combined | 12192 | 5195 | 4200 | 26.5 |

| AIS 70 | 70 | Combined | 15000 | 5195 | 4200 | 37.5 |

| AIS 80 | 80 | Combined | 12192 | 5195 | 4870 | 28.5 |

| AIS 100 | 100 | Combined | 15000 | 5195 | 4970 | 42.0 |

Ice Delivery System -Screw type

| Model | Ice Delivery Capacity

(Ton/h) |

Length (m) | Power (kw) |

| TJS-10 | 10 | 15 | 5.5 |

| TJS-15 | 15 | 15 | 7.5 |

| TJS-20 | 20 | 12 | 7.5 |

Ice Weighing Hopper

| Model | Capacity (kg) | Length(mm) | Width (mm) | Height (mm) |

| PWT200 | 200 | 800 | 720 | 1300 |

| PWT250 | 250 | 800 | 800 | 1400 |

| PWT300 | 300 | 800 | 800 | 1600 |

| PWT350 | 350 | 850 | 800 | 1700 |

| PWT400 | 400 | 900 | 800 | 1800 |

| PWT450 | 450 | 1000 | 800 | 1800 |

| PWT500 | 500 | 1000 | 800 | 1980 |

Ice Water Plant

| Model | Unit | TJ-

ICW 60 |

TJ- ICW120 | TJ-

ICW 180 |

TJ-

ICW 240 |

TJ-

ICW 312 |

TJ-

ICW 360 |

| Capacity | T/d | 60* | 120 | 180 | 240 | 312 | 360 |

| Flow Rate | m³/hr | 2.5 | 5 | 7.5 | 10 | 13 | 15 |

| N.Ref.Cap. | kw | 124 | 260 | 390 | 520 | 675 | 780 |

| Inst.Ref.Cap. | kw | 139.1 | 289.4 | 441.9 | 571.7 | 725 | 815.4 |

| Inst.Power | kw | 36.8 | 66.1 | 97.6 | 121.6 | 165.8 | 196.8 |

| R.Power | kw | 27.6 | 52.9 | 78.1 | 97.3 | 132.6 | 157.4 |

| System COP | kw/kw | 3.99 | 4.13 | 3.87 | 4.14 | 3.68 | 4.15 |

| Container type | ft | 20 | 20 | 40 | 40 | 40 | 40 |

| Insulated Tank* | m³ | 20 | 40 | 60 | 80 | 100 | 100 |

Note:“*”means supplied by customer

Working condition:R404a,380v/3ph/60hz.optional for R507A,R22,R717.

Other Application

Ready-mix

Nuclear power plant

Dam

Food Storage

Large buildings

Chemical plant