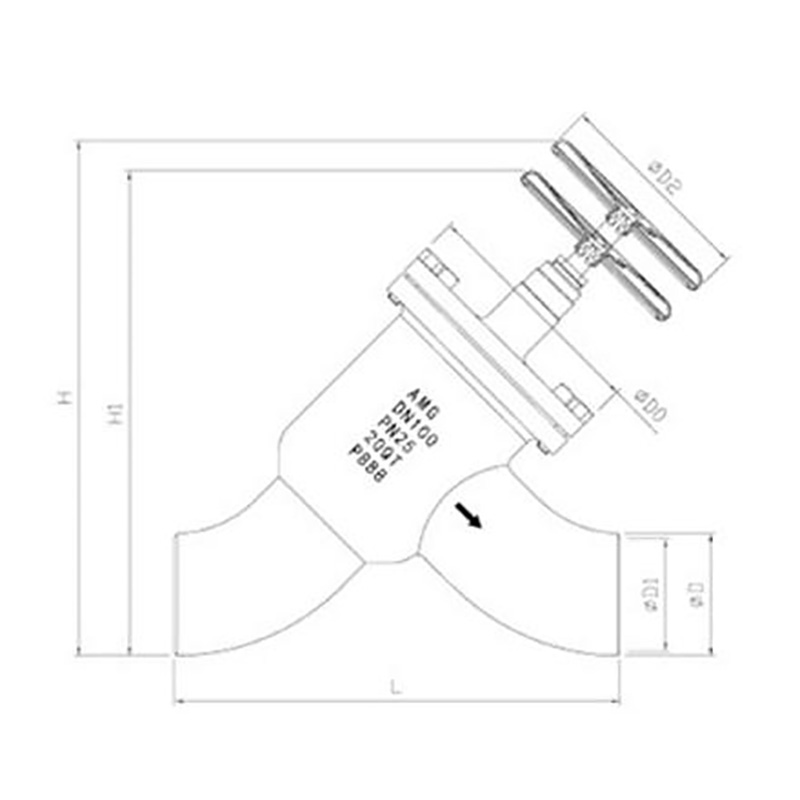

RVY100-450-D Welding Straight-Through Stop Valve

Technical Parameter

Nominal pressure: 2.5MPa

Applicable temperature:-50℃~ +150℃

Test pressure: 3.75MPa

Applicable medium: ammonia,fluorine,propane,propylene,etc.

|

Name |

Model |

Size (mm) |

Weight (kg) |

|||||

|

φD |

φD1 |

L |

φD0 |

H1 |

H |

|||

|

RVY Welding Straight-through Stop Valve |

RVY100-D |

108 |

99 |

390 |

208 |

428 |

455 |

19 |

|

RVY`125-D |

133 |

123 |

470 |

229 |

500 |

535 |

28 |

|

|

RVY150-D |

159 |

149 |

545 |

267 |

560 |

605 |

38 |

|

|

RVY200-D |

219 |

205 |

670 |

333 |

710 |

760 |

78 |

|

|

RVY250-D |

273 |

255 |

910 |

410 |

870 |

935 |

145 |

|

|

RVY300-D |

325 |

305 |

1065 |

450 |

1070 |

1155 |

288 |

|

|

RVY350-D |

377 |

355 |

1225 |

505 |

1185 |

1260 |

390 |

|

|

RVY400-D |

426 |

402 |

1380 |

565 |

1300 |

1420 |

|

|

|

RVY450-D |

480 |

456 |

1530 |

650 |

1380 |

1500 |

||

Working principle

● The axis of the valve stem of the welded stop valve is perpendicular to the sealing surface of the valve seat. The opening or closing stroke of the valve stem is relatively short, and it has a very reliable cutting action, making this valve very suitable for cutting off, adjusting and throttling as a medium.

● Once the disc of the welded stop valve is open, there is no contact between its seat and the sealing surface of the disc, and it has a very reliable cutting action. Thus, the valve is very suitable for cutting off or regulating and throttling as a medium.

● Once the welded stop valve is in the open state, there is no contact between its valve seat and the sealing surface of the valve disc, so the mechanical wear of its sealing surface is relatively small. Because the valve seat and disc of most stop valves are relatively easy to repair or replace the sealing elements, it is not necessary to remove the entire valve from the pipeline, which is very applicable to the occasion when the valve and pipeline are welded together. The flow direction of the medium has changed when passing through this type of valve, so the flow resistance of the stop valve is higher than that of other valves.

Characteristics

● The structure is simpler than the gate valve, and the manufacturing and maintenance are more convenient.

● The sealing surface is not easy to wear and scratch, and has good sealing performance. There is no relative sliding between the valve flap and the valve body sealing surface when opening and closing, so the wear and scratch are not serious, the sealing performance is good, and the service life is long.

● High pressure forging shell, reliable quality.

● The connection mode adopts direct welding, which is convenient for installation and not easy to leak.

● When opening and closing, the valve disc travel is small, so the height of the stop valve is smaller than that of the gate valve, but the structure length is longer than that of the gate valve.

● When the nominal pressure of the medium flow direction PN ≤ 16MPa, the medium generally flows in the downstream direction, and the medium flows upward from the lower direction of the valve clack; When the nominal pressure PN ≥ 20MPa, the reverse flow is generally adopted, and the medium flows down from the upper direction of the valve clack to increase the sealing element energy. When in use, the medium of the stop valve can only flow in one direction and cannot change the flow direction.

For more details and different sizes, please contact us.